We set a new standard for guardrails.

An improved guardrail that compensates for driver frustration and fatigue that has accumulated due to the closed section (2W, 3W), which is a disadvantage in existing guardrails and allows drivers to enjoy the scenery and drive safely thanks to D-beam-shaped rails.

closed guardrail

open guardrail

It is suitable as a protective rail for scenic areas, such as riversides and coastal roads because it maintains the view.

Compensates for driver frustration and fatigue

In case of a minor accident, parts are easily replaceable and maintained

Vehicle collisions can be prevented by minimizing icing by installing open rails that allow abundant sunlight

Depending on the installation location, painting is possible, and its aesthetics blends well with the surrounding environment.

It minimizes environmental pollution by reducing the amount of calcium chloride used in winter by allowing more sunlight through

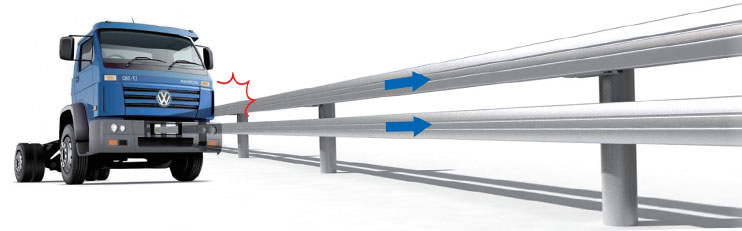

The rail has fluidity

Sliding occurs

The direction of motion changes

Protects passengers, restores the vehicle direction, and maintains vehicle speed

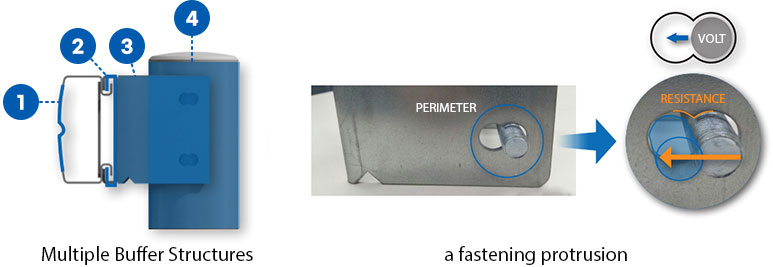

Maintains rigidity + Forms the moving impact-absorbing resistance points

Controls the performance between contrasting elements of the rigid and soft structure + ductile structure

Induces multi-stage crash

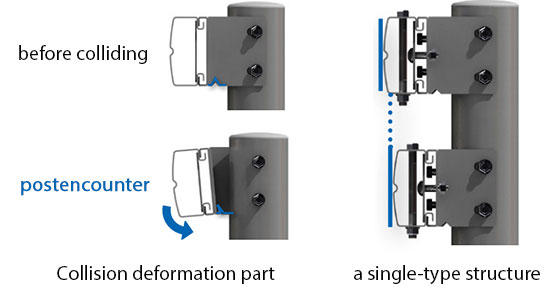

Part that deformed upon crashing Has points designed to crumple from impact

Induces deformation to the points vulnerable to impact

Stepped structure A structure with a protruding upper part

Forms a stumbling block because of the external deformation of a vehicle

| Grade | Crash speed(㎞/h) | Vehicle weight(㎏) | Impact(kJ) | Crash angle(°) | |

|---|---|---|---|---|---|

| Europe | H1 | 70 | 10,000 | 126 | 15 |

| Korea | SB2 | 65 | 8,000 | 90 | |

| SB4 | 65 | 14,000 | 160 | ||

| Grade | Crash speed(㎞/h) | Vehicle weight(㎏) | Crash angle(°) | |

|---|---|---|---|---|

| Europe | H1 | 100 | 900 | 20 |

| Korea | SB2 | 80 | 1,300 | |

| SB4 | ||||

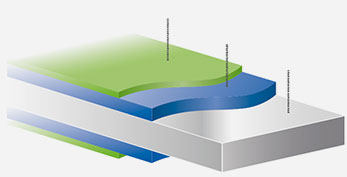

PosMAC, a ternary alloy coated steel sheet produced by POSCO, is used.

It has corrosion resistance five to ten times higher than that of hot-dip galvanized steel sheet.

Chemical-treated coating layer

(temporary rust-resistant)

PosMAC(playing layer)

Steel

| SST | GI(H) | PosMac | |||||

|---|---|---|---|---|---|---|---|

| The coating weight on both sides | 120 g/㎡ | 200 g/㎡ | 300 g/㎡ | 600 g/㎡ | 140 g/㎡ | 200 g/㎡ | 275 g/㎡ |

| 100 Hr |  |

|

|

|

|

|

|

| 1000 Hr |  |

|

|

|

|

|

|

| 1500 Hr |  |

|

|

|

|

|

|

Open Rail, Circular Support

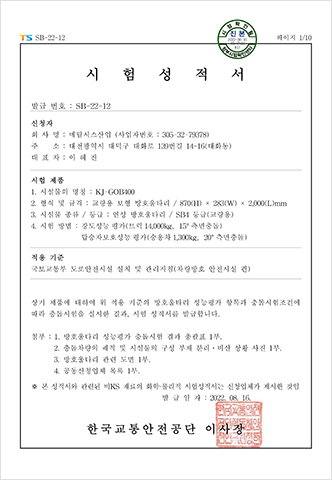

Beam safety barrier for Road / SB2 Level

Structural Strength

(8 ton Truck at 15° Side Impact)

Occupant Safety

(1.3 ton Passenger Car at 20° Side Impact)

Open Rail, Circular Support

Beam safety barrier for Road / SB4 Level

Structural Strength

(14 ton Truck at 15° Side Impact)

Occupant Safety

(1.3 ton Passenger Car at 20° Side Impact)

Open Rail, Circular Support

Beam safety barrier for Bridge / SB4 Level

Structural Strength

(14 ton Truck at 15° Side Impact)

Occupant Safety

(1.3 ton Passenger Car at 20° Side Impact)